The growth of wireless and high-speed data applications has caused the use

of coaxial cables to surpass traditional video and telecommunications cables.

With the development and standardization of coaxial cables used in various

applications, coaxial cables have become common equipment in homes, offices,

telecommunications facilities, railways, industrial plants, and

government/public safety facilities. The diversification of such applications

has led to diversification of the types, grades and manufacturers of coaxial

cables.

Coaxial cable application requirements and parameters

The beginning of everything is always to understand the problem to be

solved. For the purchase of coaxial cable, this means that you need to know the

quality of the signal that the cable needs to carry. Some of the important

factors are the frequency range and the power level of the transmitted signal.

Other factors include the radio frequency and electromagnetic environment

through which the signal passes, wiring length, and wiring difficulty. Around

the specific coaxial cable selected for a certain application, the project

budget and all institutional requirements also play an important role in

decision-making.

1. Correctly select impedance

The two main impedances used in coaxial cables are 75 ohms and 50 ohms.

Unless there is a visible marking content, the impedance of a coaxial cable

cannot be judged from the outside. If the above two impedances are confused, it

may cause damage to the device connector or the device itself, or at least

degrade system performance. Although sometimes used crosswise, 75-ohm cables are

often used for video applications, while 50-ohm cables are more commonly used

for data and wireless purposes. The type of equipment and device to be connected

determines the cable impedance to be used.

2. Correctly select the cable length according to the attenuation

Signal energy can be lost due to thermal energy caused by conductor

resistance, dielectric loss factor and other factors related to the quality of

the coaxial cable material. The attenuation of a coaxial cable represents the

energy loss per unit length of the cable. For applications where the signal

power is extremely low or the wiring requirements are extremely long, and there

is no amplifier or signal booster, a low-loss cable may be required to meet the

minimum signal strength requirements at the receiving end of the coaxial cable.

If the attenuation of the coaxial cable is so low that there is no need to use a

signal booster, even if the price of the low-loss cable is more expensive, the

use of the cable is still a cost-effective investment.

Different cables have different power ratings

Depends on the cable diameter, the type of central and outer conductors,

and the quality of the cable. Different cables have different rated maximum

processing powers. These ratings are given in the form of values under

continuous wave conditions, average values or peak values, and have different

meanings depending on the type of signal carried. In addition, it is possible to

give the rated values of the rated maximum voltage and the rated maximum

current. It should be noted that such ratings also depend on the frequency, and

cables with better safety margins should be selected. Once the rated power of

the coaxial cable is exceeded, there is a risk of unfortunate failure modes such

as electric sparks, accelerated aging, medium degradation, and combustion.

Not all coaxial cables have the same shielding performance

Coaxial cables have a variety of structure types such as braided, stranded,

foil, solid, corrugated, etc., a variety of outer conductor types, and a variety

of shielding methods. In order to further reduce the interference received or

emitted, some coaxial cables can have multiple shielding layers in addition to

the outer conductor. In addition, the use of different types of outer conductors

and shielding layers can also achieve crush resistance, higher

rigidity/flexibility and lower attenuation. For many applications, when budget

allows, the higher the quality of the outer conductor and shielding layer of a

coaxial cable, the better, and the more the number, the better.

How to wire/route?

Different applications usually have very different wiring requirements. The

wiring requirements for large outdoor industrial environments are different from

those in machinery facilities or aircraft fuselages. From wiring in equipment

assemblies to wiring in complex buildings, for almost any environment, there is

a corresponding coaxial cable that can meet its needs. For specific wiring

types, coaxial cables have several technical parameters to measure whether they

can meet the requirements, including: bending radius, maximum load or

unsupported wiring conditions, wind load, and a variety of environmental factors

and ratings. Normally, such information should be provided to the cable

purchaser, otherwise the exact details of the wiring requirements may be as

important as the electrical performance of the cable. Because some applications

make the wiring operation rougher, different sheath materials and protective

layers are usually used to assist in cable installation.

What type of connector do I need?

When using non-dedicated coaxial connectors, some coaxial cables may have

problems with oversize or undersize. Many manufacturers provide optimized

coaxial connectors for specific cables, and low PIM or low loss applications

require the use of dedicated high-performance connectors. In addition, the

coaxial connector and the cable can be connected by crimping, welding, and

toolless press-fitting. One thing to consider is that not all cables are

suitable for certain connection types.

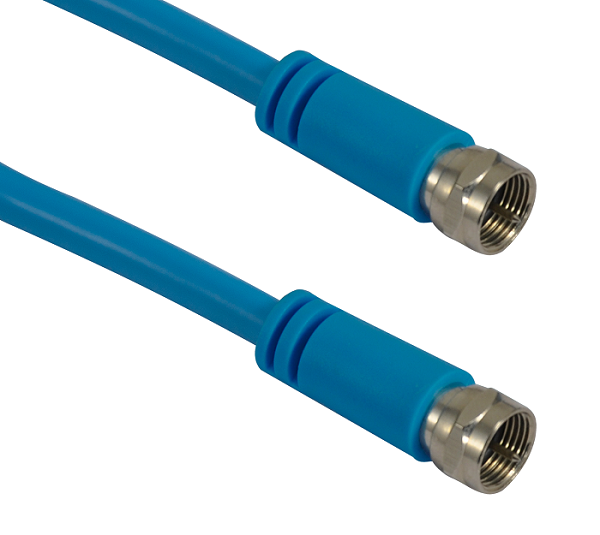

Should I buy a coaxial cable or a coaxial cable assembly?

Due to the diversity and application requirements of coaxial connectors and

cables during installation, many suppliers provide pre-assembled coaxial

components for specific purposes. For a specific application, if the cable

length, performance parameters, and coaxial connector type are known, then the

best choice is to use cable assemblies.

Institutional requirements and special equipment

Certain applications, such as military, government, avionics, aerospace and

industrial equipment, have specific regulations and requirements for coaxial

cable performance. Only by meeting the institutional requirements of these

industries, society, and governments, can cables be qualified to be used in

these fields. These requirements can be quite complex, and it is not easy to

remember them. Experts may be the best candidates for details here.

Special cable

Many special applications such as test and measurement, scientific

experiments, satellites, high-performance radars, etc. require the use of very

special coaxial cables. In addition to the above-mentioned institutional

standards, these cables usually need to meet specific applications and many

non-standard requirements. Experts can help purchasers understand the cables

that can meet specific needs one by one, and finally choose the best option.

Counterfeit cables and counterfeit goods

Unfortunately, due to profit-driven, counterfeit coaxial cables sold

illegally are more accessible to the buying crowd. The use of cables other than

genuine ones is illegal in itself and may put the safety of operators and

equipment at risk. Only choosing qualified suppliers with good historical

records and quality management systems is the best measure to prevent potential

losses caused by counterfeit coaxial cables.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик